2016-03-02 - Wolfschlugen, Germany - Thomson Industries, Inc., has helped Danish fabrics plasticator, Raaco International, achieve lower annual energy costs of 89% by switching to Thomson’s new generation electric linear actuators, the PC SeriesTM, at its plastic welding and injection moulding factory in Denmark.

Pneumatic cylinders are susceptible to pressure loss and leakage and Raaco needed an alternative to increase performance and reduce energy costs. It turned to Thomson’s authorised Danish distributor, AVN Teknik to explore the option of switching to an electromechanical solution. “We estimated that Raaco was losing nearly a third of its compression between the compressor and the point of actuation,” said Flemming Blauert, Product Specialist at AVN Teknik.

Utilising a Thomson-supplied sizing and calculation tool, Blauert found that the electromechanical actuators offered an 80% efficiency rate compared to just 15% for their pneumatic counterparts. A total cost saving of 613 euros a year per cylinder showed that the PC Series would be able to pay for themselves within three years in energy savings alone. A test installation of the Thomson’s PC SeriesTM showed further evidence of improvements in performance, productivity and savings. The electromechanical actuators proved to be three times faster than their pneumatic predecessors and required less maintenance. Raaco expected downtime during the transition of up to two days but the process went so smoothly that the actuators were working as intended in a couple of hours.

Convinced by the potential value that resulted from the test on a key injection moulding application, Raaco has ordered electromechanical replacements for its pneumatic cylinders on all of its injection moulding line and is evaluating application opportunities throughout the rest of its plant. Energy savings, speed, and reduced maintenance were the key factors in Raaco’s decision to convert to Thomson’s PC SeriesTM electric linear actuators.

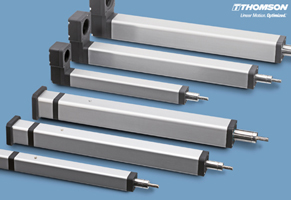

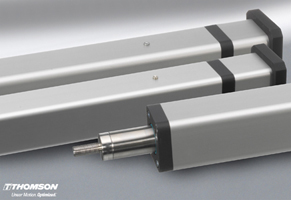

Thomson’s new generation, PC SeriesTM electric actuators are optimised to help design engineers convert from pneumatic to electric linear actuation. The units require less maintenance, simplify machine design, offer significant cost savings and are ideal for 100% duty cycle applications that require high accuracy and reliability.

For more information about Thomson’s PC SeriesTM

actuators, please visit:

http://www.thomsonlinear.com/conversion

About Thomson

With more than 70 years of motion control innovation and quality, Thomson Industries, Inc. is the industry’s premier producer of Linear Ball Bushing® Bearings and Profile Rail Bearings, 60 Case® Shafting, ground and Ball and Lead Screws, Linear Actuators, Gearheads, Clutches, Brakes, Linear Systems, and related accessories. Thomson invented the Linear Ball Bushing Bearing in 1945, and has set the standard ever since with an unsurpassed set of mechanical motion control solutions serving global commercial and aerospace & defense markets. Thomson Industries, Inc. has facilities in North America, Europe and Asia with over 2000 distributor locations around the world.

Thomson Industries, Inc., 1500 Mittel Boulevard, Wood Dale, IL 60191-1073; 1-540-633-3549; 1-540-633-0294 (Fax); Thomson@thomsonlinear.com; www.thomsonlinear.com.

About Raaco

Raaco International has been producing innovative storage solutions from its factory in Denmark for almost 60 years. 100 workers create a range of shelves and plastic drawers as well as new lines including inventory mobile storage, all of which adhere to the high standards that have helped to cement the business’ strong reputation for quality over decades.

Click to expand the images: