2016.03.16 - Wolfschlugen, Germany – Thomson Industries, Inc., a leading manufacturer of mechanical motion control solutions, has expanded its web-based sizing and selection tool for Micron® TRUE Planetary? Gearheads. The web-based MicronMOTIONEERING® is a unique, application-based sizing and selection tool that quickly and easily identifies the correct planetary gearhead for your application. The improved MicronMOTIONEERING® interface and expanded product offering, allows users to save time and boost confidence in knowing that they’ve selected the optimal gearhead for their motion control application.

Micron planetary gearheads from Thomson are used on high precision motion control applications, such as CNC cutting, material handling and many variations of packaging equipment. These applications usually require a high torque to volume ratio, high torsional stiffness, and low backlash which are the performance advantages that the Micron products offer. The upgraded user interface was designed and tested to provide a professional user experience for design engineers. The expanded MicronMOTIONEERING® now covers the full Micron offering, including the stainless steel AquaTRUETM gearheads, ideal for food and packaging applications, and the XTRUEM, a drop-in replacement for common gearheads in the market today.

“MicronMOTIONEERING® is an intuitive tool that greatly simplifies gearhead sizing and selection to help OEMs optimise their machine design in much less time than it takes using manual calculations and paper catalogue look ups. End users will find the cross reference guide and expedited delivery option a life saver for line down situations,” said Howard Horn, Product Manager Micron Gearheads at Thomson Industries. “It’s the best sizing and selection tool for gearheads available online today.”

The new upgrade allows customers to simply enter a few key application parameters and the MicronMOTIONEERING® instantly delivers all the information needed to specify and order the best gearhead for the application.

The extended capabilities of the online tool, also means it is now easier to quickly configure and download 3D models along with detailed and downloadable specifications including list price, delivery time, configuration parameters, life calculations, motor sizing and more.

The new MicronMOTIONEERING® tool is available at:

www.micronmotioneering.com.

About Thomson

With more than 70 years of motion control innovation and quality, Thomson is the industry’s premier producer of Linear Ball Bushing® Bearings and Profile Rail Bearings, 60 Case® Shafting, ground and rolled Ball Screws, Linear Actuators, Gearheads, Clutches, Brakes, Linear Systems, and related accessories. Thomson invented the Linear Ball Bushing Bearing in 1945, and has set the standard ever since with an unsurpassed set of mechanical motion control solutions serving global commercial and aerospace & defence markets. Thomson Industries, Inc. has facilities in North America, Europe and Asia with over 2000 distributor locations around the world.

Thomson Industries, Inc., 1500 Mittel Boulevard, Wood Dale, IL 60191-1073; 1-540-633-3549; 1-540-633-0294 (Fax);

Thomson@thomsonlinear.com; www.thomsonlinear.com.

Click to Enlarge Images:

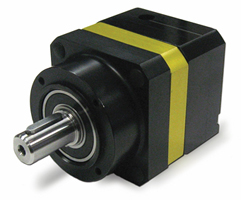

Photo 1: Thomson AquaTRUETM Planetary Gearhead. A gearhead designed to meet the strict requirements of harsh environmental applications, such as food and beverage, handling and packaging and dispensing.

Photo 2: Thomson MicronMOTIONEERING® homepage.

Photo 3: Thomson MicronMOTIONEERING® CAD model generator, showing the 3D model of a Thomson XTRUETM Planetary Gearhead for improved load capacity, lower backlash and quieter operation.

Photo 4: Thomson XTRUETM Planetary Gearhead. A precision gearhead that complements the Micron® True Planetary? Gearheads line, which is designed for improved load capacity, lower backlash and quieter operation.