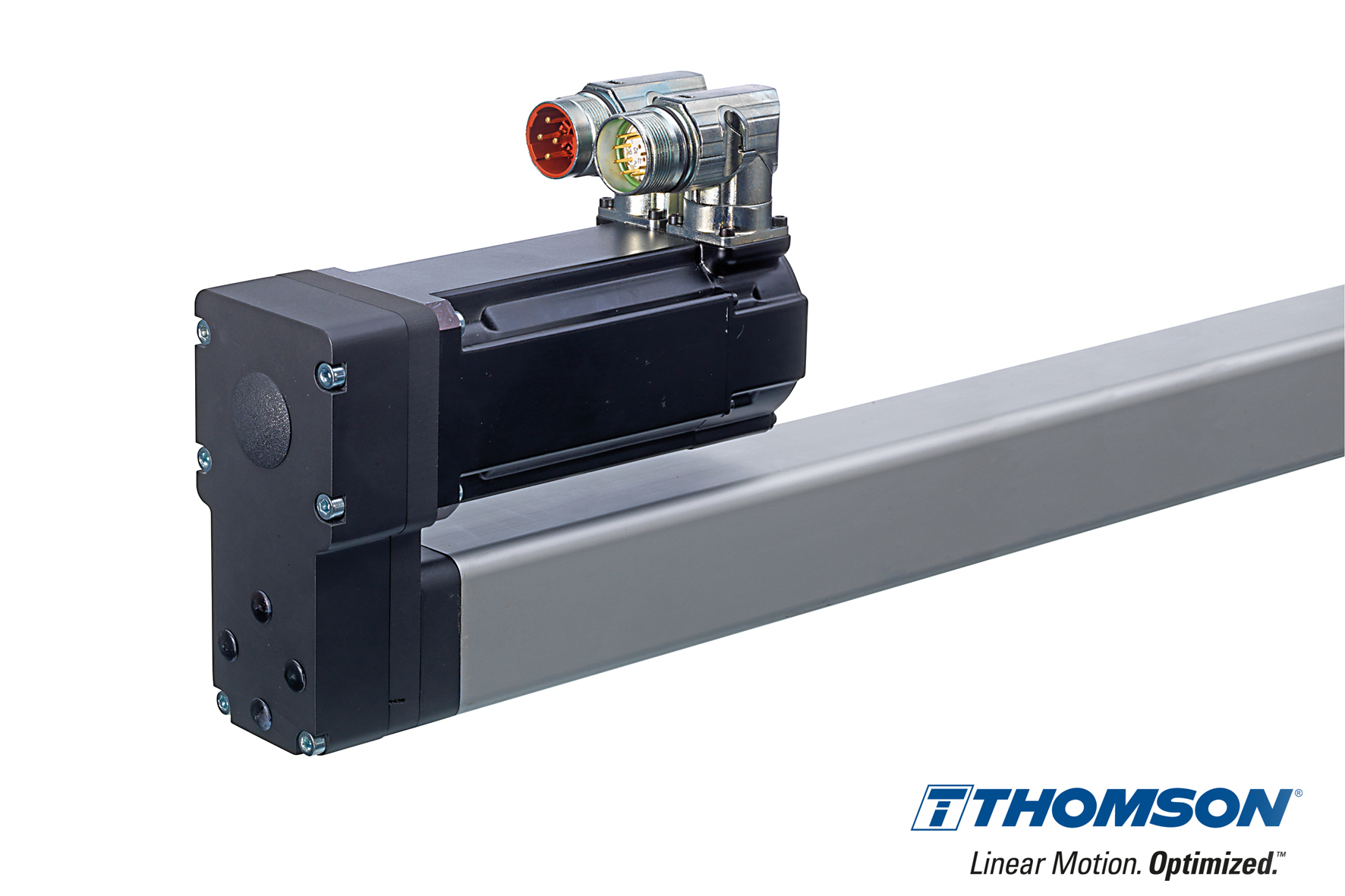

14.03.2017, Kristianstad, SWEDEN – Thomson Industries, Inc., a leading manufacturer of electromechanical motion control solutions, is now offering users of its industry leading PC Series precision linear actuators an optional, pre-mounted and pre-tested servo motor. Bundling linear actuators with servo motors simplifies ordering, reduces the need for additional validation after installation, increases reliability, and reduces the total cost of owning and operating an actuator system.

“Inconsistencies in the way in which servo motors are mated with actuators can impact performance, reliability, and eventually the performance life of both the actuator and the motor,” said Niklas Sjöström, Product Line Manager – Systems Group for Thomson. “By pre-assembling and pre-testing standard integration with our PC Series family at the factory level, we save users the trouble of sizing, selecting and mounting the right motor for their application.”

Pre-installing and configuring Kollmorgen AKM servo motors complements the industry leading capabilities of the PC Series actuators, which have been demonstrated to provide four times the travel life of any other actuator of comparable size available today, double the power and load density, 25 percent better thrust force and side load handling, as well as higher speed and longer stroke length. Integrating a servo motor so tightly with PC Series provides users with the following additional benefits:

- Optimum motor matching. All Thomson PC Series linear actuators can be ordered with a broad selection of Kollmorgen AKM servo motors, fully-integrated and tested.

- Easier sizing and selection. Because Thomson has already identified and tested a wide range of configurability options and has provided a tool that helps map applications to motor sizing, it takes less than 15 minutes to find the right combination. Downloadable and configurable 3D CAD models contribute to the solution. All parameters, including length, motor orientation, mounting adapters and screw leads, are fully customisable.

- Fast and reliable installation. Once the actuator/motor combination is selected, the unique Thomson RediMount? motor mounting system speeds implementation by reducing the time spent aligning the actuator and motor. Should you prefer using your own motor make and type, you still reap the benefits of the RediMount system, giving you the ability to seamlessly fit more than 600 different motor alternatives to the PC Series actuators. ISO standard mounting interfaces are also available to facilitate upgrades from pneumatic technologies.

- Reduced maintenance. Pre-aligning the system extends life by compensating for system alignment, complementing the maintenance benefits already gained from the PC Series’ IP65 rating and corrosion resistance.

Top quality servo motors Thomson chose to pre-install Kollmorgen AKM servo motors because of their proven, high-quality motor range, complemented by a broad array of servo drives and programmable positioning controllers for both single- and multi-axis applications. Some of the benefits include:

- Best-in-class performance with industry leading power density

- Exceptionally low cogging and harmonic distortion to ensure smooth performance

- Easy to commission and use with plug-and-play motor recognition and full-frequency auto-tuning on AKD? Series servo drives

Availability

Thomson PC Series linear actuators with an integrated Kollmorgen AKM servo motor option are available in Europe immediately. They can be selected online using tools and diagrams that simplify finding the actuator/motor combination that meets the customers’ application needs. Customers with their own brand of motor can still be benefited by the RediMount system.

About Thomson

With more than 70 years of motion control innovation and quality, Thomson is the industry’s premier producer of Linear Ball Bushing® Bearings and Profile Rail Bearings, 60 Case® Shafting, ground and rolled Ball Screws, Linear Actuators, Gearheads, Clutches, Brakes, Linear Systems, and related accessories. Thomson invented the Linear Ball Bushing Bearing in 1945, and has set the standard ever since with an unsurpassed set of mechanical motion control solutions serving global commercial and aerospace & defence markets. Thomson Industries, Inc. has facilities in North America, Europe and Asia with over 2000 distributor locations around the world.

Thomson Industries, Inc., 1500 Mittel Boulevard, Wood Dale, IL 60191-1073; 1-540-633-3549; 1-540-633-0294 (fax); Thomson@thomsonlinear.com; www.thomsonlinear.com.

Click to enlarge images: